Information and Beneficial Aspect of Siemens SCADA System as suitable automation system for every application :

Siemens SCADA System becomes the answer of the Industrial tighter and greater challenge by the days. Almost every manufacture, developer and the console maker was go in challenge to pursue the perfection that was set in not only the idea of great production process to grow up and increase the productivity but also comes to deal with any aspect that can bring the safety and effectiveness in case of whole business process.

Siemens SCADA System inline with the market standard requirements, sales objectiveness and more with the crystal clear managerial decision maker was become the reality inside the industries. And so with the “value up and cost down” stigma that grow up through the business owner or industrial manager.

By that reason, the scale of better system, solution and support developer dramatically day by the day. And so with the Supervisory and Control system that can control the whole business process and shown better data output was needed more and more.

And so the SIMATIC WinCC by Siemens SCADA System offered several beneficial aspect such as:

This Siemens SCADA System has easy scalability and efficient production analysis for any field of industries, such as: Automotive production and suppliers, chemical and pharmaceutical industry,food, beverages and tobacco industry,machine and plant engineering,energy supply and distribution,trade and service sector, plastic and rubber industry,metal processing and steel industry,paper production and processing, printing industry, transport, traffic and logistics,water treatment and wastewater purification,building services management and management of properties.

This models Siemens SCADA System was offered for Easy scalability process controlling Siemens SCADA Systems was developed for the intention of efficiency in terms of operations control and openness for special requests, such as:

Siemens SCADA System inline with the market standard requirements, sales objectiveness and more with the crystal clear managerial decision maker was become the reality inside the industries. And so with the “value up and cost down” stigma that grow up through the business owner or industrial manager.

|

| SIMATIC WinCC Siemens SCADA System by Siemens.com |

By that reason, the scale of better system, solution and support developer dramatically day by the day. And so with the Supervisory and Control system that can control the whole business process and shown better data output was needed more and more.

SIEMENS SCADA SYSTEM, THE BEST CHOICE TO INCREASE PRODUCTIVITY WITH THE BENEFICIAL ASPECT OF THE PRODUCTS

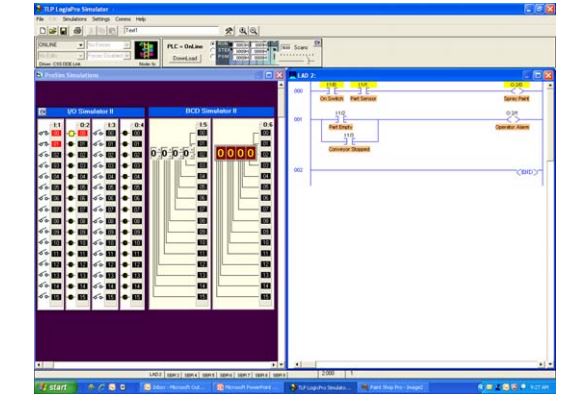

SIMATIC WinCC was developed by Siemens SCADA System to answer the challenge of industries and industrial partners as scalable and open SCADA system. It called the requirements of the future as the solution for the data Supervisory Control of modern industrial plants that continuously growing, and increasing by the day.And so the SIMATIC WinCC by Siemens SCADA System offered several beneficial aspect such as:

- Siemens SCADA System increase efficiency As key to increased productivity, SIMATIC WinCC combines efficient engineering with powerful archiving and maximum data security.It serves as the basis for efficient operations control and intelligent production analysis.

- Siemens SCADA System guarantee scalability This product offer stationary or mobile solutions for increasing requirements. For this purpose, the SIMATIC WinCC use Siemens SCADA System that totally know-how of more than 15 years across all sectors. No matter how moderate or expansive the client or end users requests – it provide the suitable solution.

- Siemens SCADA System has higher Innovation Benefit from information provision anytime and anywhere with mobile SCADA solutions –also with available tablet or smartphone hardware. The application of multi touch gestures in industrial environments opens the door to modern operating concepts.

- Siemens SCADA System pursue openness International standards as well as native script and programming interfaces, also special requests can be easily realized.

This Siemens SCADA System has easy scalability and efficient production analysis for any field of industries, such as: Automotive production and suppliers, chemical and pharmaceutical industry,food, beverages and tobacco industry,machine and plant engineering,energy supply and distribution,trade and service sector, plastic and rubber industry,metal processing and steel industry,paper production and processing, printing industry, transport, traffic and logistics,water treatment and wastewater purification,building services management and management of properties.

SIEMENS SCADA SYSTEMS PRODUCT INFORMATION

By that beneficial aspect that was promised by Siemens SCADA Systems, it wasn’t only the manufacture lips service to increasing the sales prospect. It was something happen with offered of several types of the SCADA software for any types of field and intention, such as:- WinCC/Server– for distributed client-server systems

- WinCC/Redundancy– for increased availability

- SIMATIC Process Historian– powerful, plant-wide long-time archive

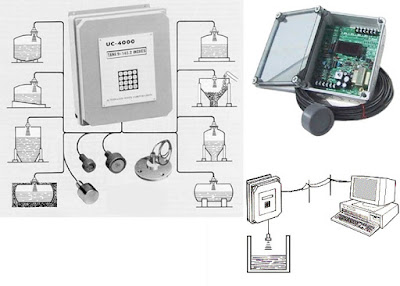

- WinCC/WebNavigator– plant operation and monitoring via the Internet/Intranet

- WinCC/WebUX– mobile access to important plant information

- WinCC/Telecontrol– integration of distributed remote stations in the telecontrol system

This models Siemens SCADA System was offered for Easy scalability process controlling Siemens SCADA Systems was developed for the intention of efficiency in terms of operations control and openness for special requests, such as:

- WinCC/UserArchive– management of user data records

- WinCC/Audit and WinCC/ChangeControl–tracking of operator actions

- SIMATIC Information Server– web-based reports of historical plant data on basis of Microsoft ReportingServices or with Microsoft Excel

- WinCC/PerformanceMonitor– production analysis on the basis of individual key performance indicators and web-based performance reports in combination with the SIMATIC Information Server