Wednesday, 22 March 2017

BEST PLC SCADA Training Institute in Chennai | Best Training Institute In Chennai,

Review Benefits SCADA Systems Automate Electrical Distribution to increase uptime and improve utilization

Rapid power transmission and distribution systems from power plants to customers in residential or office safe is a challenge today's power generation industry. Electric utilities parties must be able to meet the electricity needs of the community well, minimizing disruptions and power cuts as much as possible. Electricity utility must collect and distribute electricity from the various sources of electricity generation, many of them intermittent, and distribute to customer by utilizing automated monitoring and control of SCADA.

Substation power plants have a complex system and have varying amounts of control and operator interface points. Substation power plants will be controlled and monitored in real time by a Programmable Logic Controller (PLC) and by special devices such as circuit breakers and power monitor. Data from the PLC and the device is then transmitted to a PC-based SCADA node in the substation.

other parameters of the distribution system at the desired level.

Substation power plants have a complex system and have varying amounts of control and operator interface points. Substation power plants will be controlled and monitored in real time by a Programmable Logic Controller (PLC) and by special devices such as circuit breakers and power monitor. Data from the PLC and the device is then transmitted to a PC-based SCADA node in the substation.

BENEFITS OF IMPLEMENTING SCADA SYSTEMS FOR ELECTRICAL DISTRIBUTION

SCADA implementation in the electrical distribution system is greatly assisting the authorities of electricity in various ways such as:1. Improve the performance of the electrical distribution system automatically

SCADA systems are able to make the process safer, faster and completely automated start of collecting data to provide automatic control that greatly benefits utilities. One application is when there are problems in the field Alarm they detect problems in the system, and analysis of this issue allows adjustments and corrections, often prevent the outage automatically. When there are problems e.g. outage caused by an unexpected event such as a hurricane, SCADA a sophisticated system of data collection capability helps field workers to quickly identify the exact location of outages without having to wait for customer calls.2. Data collection for the electricity distribution process automatically

As automatic control systems, SCADA able to change the system work a lot of utilities that still rely on manual labor to perform tasks automatically power distribution. This process is able to cut labor costs, making the process safer and more comfortable and minimize distractions. Modern SCADA system also features built-in redundancy and backup systems to provide sufficient reliability, and can respond more quickly and consistently than manual process.3. Alarm Monitoring System is able to detect problems that occur quickly and accurately

Excellence SCADA system is able to significantly increase the speed of recovery in the event of power outage. These problems occur when the SCADA-enabled switches and closers line so it can help isolate the location in case of a blackout by means of open automatic switch adjacent to the power switch quickly to other parts without the need for line workers to visit the site to perform a visual inspection long.4. Worker protection and detection of hazardous location automatically

Modern SCADA systems that provide multiple benefits in the security system and keeping the level of workers due to the substation and at DER connection point, the data should be collected and made available to the SCADA system so that it can detect problems that occur more quickly. DER automates monitoring in real-time with the SCADA system allows the operator to make more information more rapid adjustments, and to uncover trends and issues before a problem occurs.5. Facilitate the early detection of problems and routine equipment repairs

SCADA system improvements make it easier to do on a regular basis. For example, if a power monitoring device has a protocol and some types of hardware then with the SCADA system in more easily configured and installed. In addition some offer a DNP3 SCADA software package is required and IEC-60870-5-104 protocol so as to facilitate early detection if a problem occurs automatically.6. Improved efficiency of system performance based on the data trend analysis

SCADA is able to analyze and identify quickly and automatically condition of excess capacity and so the power can be transferred from the area approaching overload. The control system can also analyze trends and historical data also helps maintain the desired power factor, voltage level andother parameters of the distribution system at the desired level.

Conclusion

SCADA systems are designed to simplify power distribution applications with the help of PC-based software. Data collected from the electrical distribution system, with most of the data that comes in the substation to be processed in the SCADA control system so that the process control can be run automatically, quickly and accurately.Industrial Automation in India | PLC SCADA DCS Training in Chennai,

7 Strategies to Developing SCADA Security:

Development of the industry, makes more complex problems faced related to control systems and security. In general, SCADA is still relevant enough to be used as a control system that is capable of controlling several machines control in different areas. In line with the increasing fragility of attacks against SCADA cyber attack that also need proper treatment.

SCADA security systems today require the integration of several functions of controllers such as firewalls, proxy servers, operating systems, coating application systems, communications, and policies and procedures. For the implementation of SCADA security strategy then you need security measures to keep the network as follows:

SCADA security systems today require the integration of several functions of controllers such as firewalls, proxy servers, operating systems, coating application systems, communications, and policies and procedures. For the implementation of SCADA security strategy then you need security measures to keep the network as follows:

1. BORDER ROUTER AND FIREWALLS

Cyber attacks are usually carried out by sending the software to penetrate the internal private network. If the security system is not protected SCADA Firewalls are configured correctly then your security system is not good enough to protect passwords, IP addresses, files and so on.2. PROXY SERVERS

Packets of data sent or passing through TCP / IP should have been entered in the resource control layer applications such as Hyper Text Transfer Protocol (HTTP) and Simple Mail Transfer Protocol (SMTP). To strengthen the security system SCADA proxy server acts as a firewall to protect the traffic between a protected network and the Internet. These systems are relatively safe although security with proxy servers will not eliminate the threat of the layer attacks application.3. OPERATING SYSTEMS

As the brain of the computer system, the operating system became the main target of cyber attacks. There are 2 options for securing this system namely through the operating system upgrade to newer versions or migration by replacing opeating system to a higher version. For the safety of Operating Systems should really upgrade to the latest version and there is no compromise for any irregularities that exist.4. APPLICATIONS

Some viruses are intentionally sent to undermine the security of SCADA systems such as buffer overruns, worms, Trojan Horse, Active-X5 codes, and other malicious programs that we need to anticipate. Viruses and works by paralyzing anti-virus software and bypassing the firewall as if it had no security protection there5. POLICIES AND PROCEDURES

In addition to programs designed to address cyber attacks, it is necessary also the policies that govern the discipline of the user in performing the procedure. The policies and procedures include the selection of a secure password with a combination for example with at least one symbol, a capital letter and a number, and should be more than eight characters.6. SCADA FIREWALLS

SCADA network security can be strengthened with layers of firewalls between the system SCADA network and the Internet. System security threats are often due to internal factors such as the employee who accidentally did not record the procedures performed and it turns out it can be compromised using the hacking method that is similar to what he did.7. SCADA INTERNAL NETWORK DESIGN

Internal SCADA network must have its own IP and run by using intelligent switches and sub-masking techniques appropriate to protect the system from cyber attack. The use of Ethernet Wireless and Wired Equivalent Protocol (WEP) can be an alternative to change the default name of the Service Set Identifier6 (SSID).Conclusion

Supervisory Control and Data Acquisition (SCADA) system is the important control processes in many countries. This system performs important functions vital to many companies such as electric power companies, gas - natural, petroleum, water treatment, sewage treatment, and even the railway. However, considerations in terms of safety in the design of this system have received less attention, so the potential for interference from unauthorized access can occur. This review above will provide you several important phases to protect your system from cyber attack. By learning more methods you will get alternatives and the implementation of effective and economical control system.Tuesday, 14 March 2017

Contact Best PLC & SCADA Training Institute in Chennai | Hindustan Automation,

Flow and Density Meter Features and Specification to measures the liquid or gaseous sample density

The Flow and Density Meter is a device used to measure the flow or quantity of gas or liquid rate is moving through the pipeline. Flow measurement applications are very diverse. It is known that each case has its own restrictions and requirements engineering. The flow meter called by many names. It based on the specific industry; but the function, flow measurement, it is still the same.

This Flow and Density Meter is a device that measures the liquid or gaseous sample density. Digital density meters are used in the petroleum, pharmaceutical, chemical industry, and food and beverage quality control. Density meter works by measuring the oscillation in a glass tube containing the sample.

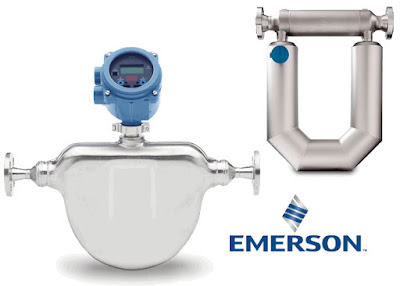

MICRO MOTION ELITE PEAK PERFORMANCE CORIOLIS FLOW AND DENSITY METER

The design of ELITE Coriolis Flow and Density Meter comes to provide accurate, frequent flow measurement environment and even the most challenging applications. This product comes with an unprecedented flow measurement of liquids and gases and the flow of a multi-stage intensity,Flow and Density Meter Motion ELITE meters provide an unprecedented flow of density and performance measurement. It has the function to provide control and ultimately confidence in the liquid, gas and slurry application of the most complex and challenging you. Achieve the benefit of the main flow

This Flow and Density Meter tool is able to achieve the best fit to measure your flow with a wide range of flow tube design. It includes the level of coverage of the service is best for your application. You can take the benefit from peak performance in the design of drying them with a variety of industry approval for use in healthcare applications strictly regulated. You can use this subject to a wide range of applications platform, including health coverage, cryogenic and high pressure.

THE FEATURES OF ELITE CORIOLIS FLOW AND DENSITY METER

There are many features of this Flow and Density Meter product, some of them are:1. Get the sensitivity of the unmatched stability measurement from this unique measure design.

2. Achieve an unprecedented flow and density measurement of performance in the most difficult of the liquid, gas and slurry application.

3. Advantage in real-time and in the process ensure measurement integrity check smart meters.

4. Increase scalability with a wide range of health coverage, including applications, cryogenic and high pressure

5. Achieving outstanding measure of confidence with the highest fluid immunity, process and environmental impact

6. You can select the models which are available in 316L stainless steel, C-22, nickel alloys and materials super duplex

7. Interact with 3D models to learn more about ELITE Coriolis flow and density meters

Practical application of the Coriolis Flow and Density Meter will affect the overall operating principle of the Coriolis flow meter involves borne vibration flow tube through which the liquid passes. Vibration was not completely circular. It provides a frame of reference rotating Coriolis effect

CONCLUSION

Flow and Density Meter has many features and specification to measures the liquid or gaseous sample density. While specific methods vary according to the design of flow meters, sensors monitor and analyze changes in the frequency, phase shift, and the breadth of the flow tube vibrating in.ABB’s Contrac Electrical Linear Actuator-Industrial Automation in India | PLC SCADA DCS Training in Chennai,

ABB’s Contrac Electrical Linear Actuator :

Electric linear actuator is one of integral part in most industrial sector. In the process of automation, actuators are responsible for positioning valves and vanes, etc to control energy, mass and the flow of materials. The Contrac actuator system designed under concept of linear actuators that has already common in the field of industry over 50 years ago. Unlike their predecessors, Contrac fulfills the trend towards actuators as an intelligent field device that has increased capability, connectability and smart visualization systems by integrating into other devices like bus systems.

Electric linear actuator has four main features including continuous positioning, overload-proof at end positions, high protection class, and long service intervals. The increasing overload capacity making it free from dependent torque switch-off while running. The high protection class, make Contrac is possible to be installed in the field that has high leak risk possibility.

Image by http://new.abb.com

- Highly compatible with fieldbus device

- Compatible with the more traditional control methods

- Has a self-monitoring facility

- Facilitate diagnostics systems and can be showed via graphic user interface

- Fail-safe technical data enabled

In addition to the rich of functions provided, it also comes with support of asynchronous motor. The motor recognized as proven in its reliability and safety. Not only limited to the durable and powerful motor, the Contrac also come with up-to-date frequency converters, which made it super flexible. Users can set various torque and stroke time with option of adapting various parameters to the control elements or the process. These all of new features ensures operational reliability and facilitate further needs for monitoring, maintenance and service.

For easier monitoring system, Electric linear actuator Contrac also support the integration to DTM (Device Type Manager). The Contrac DTM uses graphical user interface on a PC or laptop to configure all the actuator functions including diagnostics, maintenance and service information.

Who doesn’t require any of that smart function still can access the basic functions via push buttons and LEDs on the commissioning and service field of the power electronic unit.

Further requirement of decentralized intelligence can be realized using PROFIBUS DP communication system. This method provides many benefits including cutting down on wiring, reduce commissioning time, and documentation. When paired to the PROFIBUS DP communication it supports cyclic data exchange, parameterization or configuration through acyclic communication, diagnostics and configuration using GSD files.

Electric linear actuator has four main features including continuous positioning, overload-proof at end positions, high protection class, and long service intervals. The increasing overload capacity making it free from dependent torque switch-off while running. The high protection class, make Contrac is possible to be installed in the field that has high leak risk possibility.

ELECTRIC LINEAR ACTUATOR CONTRAC PROVIDES A COMBINATION OF PROVEN MECHANICAL COMPONENTS AND MICROPROCESSOR ELECTRONICS

As the name suggested, CONTRAC, was defined as “Control and Actuator”, refers to the new generation of compact actuator that provides a combination of proven mechanical components and microprocessor electronics. Here are the superiorities of Contrac as a compact electric linear actuator:- Highly compatible with fieldbus device

- Compatible with the more traditional control methods

- Has a self-monitoring facility

- Facilitate diagnostics systems and can be showed via graphic user interface

- Fail-safe technical data enabled

In addition to the rich of functions provided, it also comes with support of asynchronous motor. The motor recognized as proven in its reliability and safety. Not only limited to the durable and powerful motor, the Contrac also come with up-to-date frequency converters, which made it super flexible. Users can set various torque and stroke time with option of adapting various parameters to the control elements or the process. These all of new features ensures operational reliability and facilitate further needs for monitoring, maintenance and service.

ELECTRIC LINEAR ACTUATOR COMMUNICATION OPTIONS

For controlling flexibility, Electric linear actuator Contrac can be controlled using conventional signals as well as with any new system concept like fieldbus. This is following the concept of an intelligent actuator that is able to communicate using RS 232 interface or via HART protocol using an FSK connection, or fieldbus connection. Users can pair the actuator using FSK and fieldbus through optional features.For easier monitoring system, Electric linear actuator Contrac also support the integration to DTM (Device Type Manager). The Contrac DTM uses graphical user interface on a PC or laptop to configure all the actuator functions including diagnostics, maintenance and service information.

Who doesn’t require any of that smart function still can access the basic functions via push buttons and LEDs on the commissioning and service field of the power electronic unit.

Further requirement of decentralized intelligence can be realized using PROFIBUS DP communication system. This method provides many benefits including cutting down on wiring, reduce commissioning time, and documentation. When paired to the PROFIBUS DP communication it supports cyclic data exchange, parameterization or configuration through acyclic communication, diagnostics and configuration using GSD files.

CONCLUSION

With the ABB’s electric linear actuator, manufacturer can improve their end of automation process by taking benefits of an intelligence actuator system provided in the Contrac. Advanced communication integration, smart software and rugged construction make it an ideal option for increasing the overall automation process productivities.

Subscribe to:

Posts (Atom)