Schneider Electric EcoStruxure Business Models For Smart Machines; to help the business growth for the modern industrial life :

Schneider Electric Business Models For Smart Machines is one of a high achievement and greater aspect in so many things which comes to the today world. This condition could see in any field that happen in humans life. From the educational aspect to the industrial fields, especially the manufactures operational plans.

This condition of course push the people who worked with that, just try to reach a following condition so they can increase they productive and achieve higher and following aspect in term of Schneider Electric Business Models For Smart Machines process.

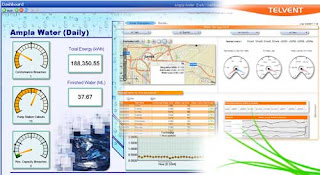

Image by https://www.schneider-electric.co.uk

Due to the fact, thats why there are so many company are go in pursue to try to reach a higher level in conditional act so they could brings a greater ideas to those following aspect. Here in this article we would take a closer review for one of former name manufacture which has been recognize widely by the world of industries called Schneider Electric. We put the the focused to one of Schneider Electric product family called business models for smart machines.

By using the EcoStuxure products, people are able to operate it through several operational aspect from, packaging automation, material handling, hoisting control, material working control, pumping control, HVAC control, systems solution, to the food and beverage machinery solutions.

This condition of course push the people who worked with that, just try to reach a following condition so they can increase they productive and achieve higher and following aspect in term of Schneider Electric Business Models For Smart Machines process.

Due to the fact, thats why there are so many company are go in pursue to try to reach a higher level in conditional act so they could brings a greater ideas to those following aspect. Here in this article we would take a closer review for one of former name manufacture which has been recognize widely by the world of industries called Schneider Electric. We put the the focused to one of Schneider Electric product family called business models for smart machines.

Schneider Electric EcoStruxure Business Models For Smart Machines; A Greater Idea to Grant Business Excellence

Using the Schneider Electric Business Models For Smart Machines to help the business growth well are one of the greaters idea for the modern industrial life. Involved any types of technology in single shot of systemic working chain has kind be nice for anyone who looking through a better process. Business models for smart machines, offered great idea for anyone who looking through a greater aspect for anybody which use if. Here are several features which offered by.• Schneider Electric Business Models For Smart Machines Flexibility Aspect

Bringing the idea for the operator this products are design and offered the ability for operator to changing machines and production, all for what industries needed.• Efficiency Aspect

What a good solution which could help business growth fast? Of course people will answer with the efficiency in any aspect, and this product are offered to improve it. The results could affect, resources, employees and of course the machinery.• Schneider Electric Business Models For Smart Machines Connectivity Aspect

The connectivity also become the main spirit for whom which running kind of business. This product help users to increase connectivity for everyone, everything, and everywhere all in real time.• Schneider Electric Business Models For Smart Machines Safety Aspect

What was the main idea of working? Of course it all about the safety aspect. This element are the main and important idea for people, assets and environments which involved with the business process.By using the EcoStuxure products, people are able to operate it through several operational aspect from, packaging automation, material handling, hoisting control, material working control, pumping control, HVAC control, systems solution, to the food and beverage machinery solutions.