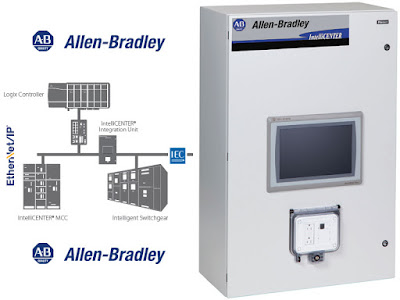

Allen-Bradley IntelliCenter Integration Unit strategic part of the integration unit to create one operating environment based on users control system needed

Allen-Bradley IntelliCenter Integration Unit is strategic part of the integration unit to create one operating environment based on users control system needed. This device widely to be used to unify power and process systems within the appropriate process especially to fullfill the standard hardware aspect of the Intelligent Packaged Power solution. This standard equipment quality make this longlife to be used in in North America.

Allen-Bradley IntelliCenter Integration Unit offers communication system with devices through the IEC 61850 standard in several areas of control systems if applied and combined as integration unit the Logix and FactoryTalk® environments. This integration unit was compatible with software to bring IEC 61850 traffic into Logix architecture.

Image by https://ab.rockwellautomation.com

Allen-Bradley IntelliCenter Integration Unit contains a Stratix Security Appliance and offers faceplates system to help user more friendly to verify the appropriate device. The effect of easy verification process make user more accurate accommodate system for your application and deliver a common user interface systems.

Allen-Bradley IntelliCenter Integration Unit generates a layout drawing, single-line diagram to create one operating environment. This environment building used to enter general MCC setup information for many purposes. One of critical purposes is delivers data information with key characteristics, add units. All of them was needed and can be created with the MCC design.

Allen-Bradley IntelliCenter Integration Unit was designed to meet global application requirements for many application providing the advantages you need in your competitive environment. For practice in process, user can combine rugged durability and premium quality in same time implementation. In this collaboration, this system Can integrate control and power into one centralized package. This can be a common experience when you used appropriately.

Allen-Bradley IntelliCenter Integration Unit offers communication system with devices through the IEC 61850 standard in several areas of control systems if applied and combined as integration unit the Logix and FactoryTalk® environments. This integration unit was compatible with software to bring IEC 61850 traffic into Logix architecture.

Allen-Bradley IntelliCenter Integration Unit features enable to delivers ease-of-use

Allen-Bradley IntelliCenter Integration Unit uses standard hardware for communication bridging that make this integration unit enable to delivers ease-of-use. Allen-Bradley IntelliCenter Integration Unit composed fragile component and consists of a Stratix® 5700 switch. For long time implementation, this switch used for aggregation of device connections. Finally, the segmentation of this integration unit is completed.Allen-Bradley IntelliCenter Integration Unit contains a Stratix Security Appliance and offers faceplates system to help user more friendly to verify the appropriate device. The effect of easy verification process make user more accurate accommodate system for your application and deliver a common user interface systems.

Allen-Bradley IntelliCenter Integration Unit offers options for PanelView™ terminal

Allen-Bradley IntelliCenter Integration Unit offers options for PanelView™ terminal to be more accurately in measurement and control system over all. This terminal used for data representation if unsecured upstream connections installed. This installment system are required Includes a ControlLogix® or CompactLogix™ controller rack.Allen-Bradley IntelliCenter Integration Unit generates a layout drawing, single-line diagram to create one operating environment. This environment building used to enter general MCC setup information for many purposes. One of critical purposes is delivers data information with key characteristics, add units. All of them was needed and can be created with the MCC design.

Allen-Bradley IntelliCenter Integration Unit enable to be easier in configuration and selection tools application

Allen-Bradley IntelliCenter Integration Unit compatible with Low Voltage Motor Control Centers with high performance packaging solution. This is enable to be easier in configuration and selection tools application to design your CENTERLINE MCC line up with schematic drawings customized. Customization system was having important role to your project requirements at all condition.Allen-Bradley IntelliCenter Integration Unit was designed to meet global application requirements for many application providing the advantages you need in your competitive environment. For practice in process, user can combine rugged durability and premium quality in same time implementation. In this collaboration, this system Can integrate control and power into one centralized package. This can be a common experience when you used appropriately.