Simplify Water control based on Water Management Suite (WMS) SCADA System :

Water management in the operating system is essential to be controlled. In some cases for example water treatment operator wants to look at chemical usage then he needs control system which is easy to be used. SCADA has functions to control the device for displaying operational data in real time both the operating system, trend data, until the alarm. If you want the integration between distribution system with system AMR (Automatic Meter Reading that designed to read the meters automatically) or it could be that you have a desire to incorporate online instrumentation with test results from the laboratory and then this system could not do it, you have to use others system. The solution is Water control system based on Water Management Suite (WMS) SCADA System. Please consider if you want to use it, analysis of data setting was needed for sampling from several databases, so it needed a lot of complex coding.

WMS itself works by plugging into a database from an application that is in a water district including the System Graphical Information (GIS), a system of meter reading (AMR / AMI), Maintenance Management System (MMS), Information Management Laboratory (LIM) system, SCADA, power systems, as well as various monitoring. If everything has been connected, the data will be checked and collaborate so that there are reports the aspects that is used for an operation of the plant.

This data will be tested before it is used for a report. Statements in this case contains a sufficiently relevant data in order to help make a decision that is accurate, solid and reliable. One of the most common application is in leak detection. Within this application, software data collection balance into a gathering system and may indicate an imbalance. In the southern California city, WMS is used for a mass balance, where data is collected every week exactly in some places.

WMS also used as effectiveness. In an application, generally a software tool used to study the performance of the system, either individual processes, as well as for each device. Where this software then participated in a detailed methodology that has the title OEE (www.oee.com) as determinants of effectiveness.

Where these factors are used to understand the performance of a place on every machine, with a notice period, the quality of water produced, until the number of levels that have been implemented including the downtime

SCADA is assumed for the operation and also for the operation of waste water. However, SCADA is the first step to obtain the best operation achievement. The next step is WMS, where the tool is to add to the primacy of process, maintenance, and operations.

WHAT IS WATER MANAGEMENT SUITE (WMS)

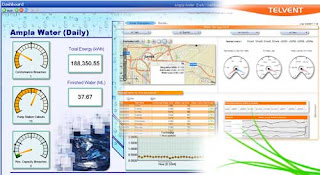

WMS is a software that consists of core components with a separate module that can be used for setting water and sewage treatment. This module is referred to as a site, not as a standalone system with the WMS used as a commercial solution to address all the challenges. For internal US application, there are an awful lot of information related to water management suite in some water industry. For example, Schneider Electric has two WMS system, which is Citect's Ampla ™ and Telvent WMS. Both of these systems can be used simultaneously or separately.WMS itself works by plugging into a database from an application that is in a water district including the System Graphical Information (GIS), a system of meter reading (AMR / AMI), Maintenance Management System (MMS), Information Management Laboratory (LIM) system, SCADA, power systems, as well as various monitoring. If everything has been connected, the data will be checked and collaborate so that there are reports the aspects that is used for an operation of the plant.

MORE UNDERSTAND THE CONCEPT OF A WMS

WMS works by some of the trending analysis of measurement data of water. Trend function in this case is as widely used in the analysis of SCADA software. SCADA design, has limitations for analyzing the data. If you want a lot of options it can use the Operational Data Management System (ODMS), which is connected to the SCADA due to its ability to view the data in a database and then analyze the data, to delete data that is not desirable.This data will be tested before it is used for a report. Statements in this case contains a sufficiently relevant data in order to help make a decision that is accurate, solid and reliable. One of the most common application is in leak detection. Within this application, software data collection balance into a gathering system and may indicate an imbalance. In the southern California city, WMS is used for a mass balance, where data is collected every week exactly in some places.

WMS also used as effectiveness. In an application, generally a software tool used to study the performance of the system, either individual processes, as well as for each device. Where this software then participated in a detailed methodology that has the title OEE (www.oee.com) as determinants of effectiveness.

Where these factors are used to understand the performance of a place on every machine, with a notice period, the quality of water produced, until the number of levels that have been implemented including the downtime

No comments:

Post a Comment