Basic Priciple, Advantages and Disadvanatges of Ultrasonic Level Sensors and Product Types Suggestions:

Ultrasonic Level Sensors uses the similar concept of the well-known sonar systems. We are all familiar with the sonar technology as a time-tested device to monitor the liquid deeps and bottoms like sea or underwater objects. Ultrasonic Level Sensors better for particular tasks like measuring liquid in the tank. Ultrasonic Level Sensors optimized for uses in the air with similar function as liquid level indicators.

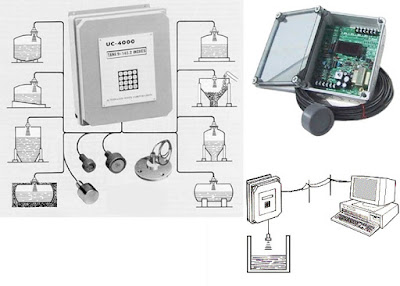

In principle, Ultrasonic Level Sensors comprise of two important components namely: control box and transducer. They both work together and inseparable. Transducer is also called as sensor. In the site, transducer is placed at the top of the tanks pointing downward to the liquid surface. The signal outputted by the transducer will deploy through the air down to the liquid surface. The signal sent doesn’t penetrate below the surface, but it will reflected back to the transducer. This echo then translated into data that indicating the deep level of the liquid in the tank.

Moreover, to keep the data accurate, there particular conditions to be fulfilled such as amount of gravity and viscosity. In addition, see more advantages of this sensor as below:

- Will last up to 20 more years with proper installation

- Fumes inside tank and vapor condensation do not influence transducers. Many claim that fume will absorb the ultrasonic signal, but that’s not true at all. The only matter is depending on the product quality and method of installation. Moreover, transducers are firmly and hermetically sealed. Then they save to be placed in the liquid and immersing in liquid not causes damage.

- Transducers are available in various shapes and material housing, so they are very adaptable to various environments and applications. The housings could be made from stainless steel, explosion-proof materials, and heat-resistant materials, PVC, Teflon and many more.

- Using the right control box, users can do multiplexing. They can monitor different tanks through one control box.

- Not applicable for liquids that produces thick foam

- Requires clear liquid surface

In the lower class are the Model UL 1000 and Model UL-100, which both designed to monitor 1 tank. They keep the similar powerful feature for various applications. Finding it very great, all of the Automated Sonix’s Ultrasonic Level Sensors supported with optional RS232C computer output giving you chance for further analysis.

Among available Ultrasonic Level Sensors in the market, Automated Sonix is the world’s leading company that provides a wide array of Level Sensors. Here is where you can go for the best non-contact liquid Level Sensors and tank Level Controls. You can use Ultrasonic Level Sensors optimized for uses in the air with similar function as liquid level indicators.

In principle, Ultrasonic Level Sensors comprise of two important components namely: control box and transducer. They both work together and inseparable. Transducer is also called as sensor. In the site, transducer is placed at the top of the tanks pointing downward to the liquid surface. The signal outputted by the transducer will deploy through the air down to the liquid surface. The signal sent doesn’t penetrate below the surface, but it will reflected back to the transducer. This echo then translated into data that indicating the deep level of the liquid in the tank.

Moreover, to keep the data accurate, there particular conditions to be fulfilled such as amount of gravity and viscosity. In addition, see more advantages of this sensor as below:

THE ADVANTAGES OF ULTRASONIC LEVEL SENSORS

Ultrasonic Level Sensors is easy to be set and forget for minimize maintenance cost, as there are no need of regular cleaning, sealing or replacing elements. This sensor is also no need calibration for smart set up system. In addition user can get other benefit as below:- Will last up to 20 more years with proper installation

- Fumes inside tank and vapor condensation do not influence transducers. Many claim that fume will absorb the ultrasonic signal, but that’s not true at all. The only matter is depending on the product quality and method of installation. Moreover, transducers are firmly and hermetically sealed. Then they save to be placed in the liquid and immersing in liquid not causes damage.

- Transducers are available in various shapes and material housing, so they are very adaptable to various environments and applications. The housings could be made from stainless steel, explosion-proof materials, and heat-resistant materials, PVC, Teflon and many more.

- Using the right control box, users can do multiplexing. They can monitor different tanks through one control box.

DISADVANTAGES OF ULTRASONIC LEVEL SENSORS

As part of control system, beside all advantages of ultrasonic level sensor as mention above, user have to know disadvantages as below:- Not applicable for liquids that produces thick foam

- Requires clear liquid surface

ULTRASONIC LEVEL SENSORS FROM AUTOMATED SONIX CORP

To meet a wide array of different level measuring of liquid in the tank, Automated Sonix provides numbers of Level Sensors ranging from the models that built-in with Digital Indication and products with no digital Indication. One example is the Model UC-4000. This model designed to monitor up to 9 tanks regardless of the size. It offers smart features like automatic scans actions, automatic display level, volume or optional weight of each tank in sequent. The Model UC-4000 designed to be used for any liquids. To monitor up to 9 tanks, it only need one control box and everything will function properly. In practice, it will automatically monitor and all tanks.In the lower class are the Model UL 1000 and Model UL-100, which both designed to monitor 1 tank. They keep the similar powerful feature for various applications. Finding it very great, all of the Automated Sonix’s Ultrasonic Level Sensors supported with optional RS232C computer output giving you chance for further analysis.

No comments:

Post a Comment