Flow and Density Meter Features and Specification to measures the liquid or gaseous sample density

The Flow and Density Meter is a device used to measure the flow or quantity of gas or liquid rate is moving through the pipeline. Flow measurement applications are very diverse. It is known that each case has its own restrictions and requirements engineering. The flow meter called by many names. It based on the specific industry; but the function, flow measurement, it is still the same.

This Flow and Density Meter is a device that measures the liquid or gaseous sample density. Digital density meters are used in the petroleum, pharmaceutical, chemical industry, and food and beverage quality control. Density meter works by measuring the oscillation in a glass tube containing the sample.

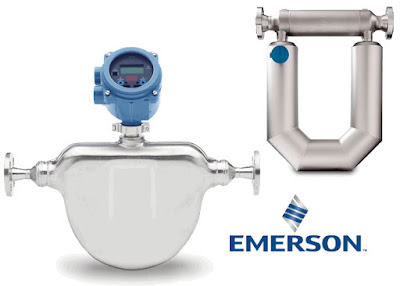

MICRO MOTION ELITE PEAK PERFORMANCE CORIOLIS FLOW AND DENSITY METER

The design of ELITE Coriolis Flow and Density Meter comes to provide accurate, frequent flow measurement environment and even the most challenging applications. This product comes with an unprecedented flow measurement of liquids and gases and the flow of a multi-stage intensity,Flow and Density Meter Motion ELITE meters provide an unprecedented flow of density and performance measurement. It has the function to provide control and ultimately confidence in the liquid, gas and slurry application of the most complex and challenging you. Achieve the benefit of the main flow

This Flow and Density Meter tool is able to achieve the best fit to measure your flow with a wide range of flow tube design. It includes the level of coverage of the service is best for your application. You can take the benefit from peak performance in the design of drying them with a variety of industry approval for use in healthcare applications strictly regulated. You can use this subject to a wide range of applications platform, including health coverage, cryogenic and high pressure.

THE FEATURES OF ELITE CORIOLIS FLOW AND DENSITY METER

There are many features of this Flow and Density Meter product, some of them are:1. Get the sensitivity of the unmatched stability measurement from this unique measure design.

2. Achieve an unprecedented flow and density measurement of performance in the most difficult of the liquid, gas and slurry application.

3. Advantage in real-time and in the process ensure measurement integrity check smart meters.

4. Increase scalability with a wide range of health coverage, including applications, cryogenic and high pressure

5. Achieving outstanding measure of confidence with the highest fluid immunity, process and environmental impact

6. You can select the models which are available in 316L stainless steel, C-22, nickel alloys and materials super duplex

7. Interact with 3D models to learn more about ELITE Coriolis flow and density meters

Practical application of the Coriolis Flow and Density Meter will affect the overall operating principle of the Coriolis flow meter involves borne vibration flow tube through which the liquid passes. Vibration was not completely circular. It provides a frame of reference rotating Coriolis effect